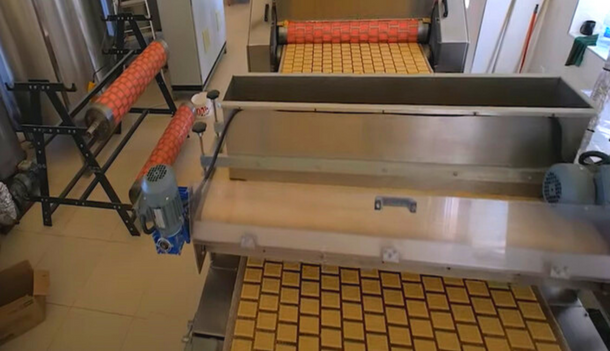

Cake Production

Requirements, challenges for the Cake production process

-

Powder adheres to the conveyor surface leading to dirt, causing product loss, disrupting production because of frequent maintenance time

-

Cutting strands of raw dough on belt surface leads to reduced life time of belt

-

Unstable product positioning

-

Continuous temperature transition at different stages

Product forming stage

-

Outstanding wear resistance, does not cause belt fraying during loading

-

Conveyor surface flat, smooth, closed without holes, thus helping to minimize contamination on the surface, easy to clean

-

Good chemical resistance thus increasing the life of the conveyor belt

Application stage of cake cooling tunnel

-

Continuous product positioning and accurate product flow, uniform product positions

-

Easy product release, limiting product sticking on the conveyor

-

Good temperature resistance, from -40°C~ 100°C, good response to sudden temperature transition in each stage

-

Excellent conveyor belt surface, comparable to stainless steel conveyor belt surface in the food field

View more link product: https://demo-mhp.thuythu.vn/en/product/food-grade-belts/

Link document: https://demo-mhp.thuythu.vn/en/document-mhp/

Contact an expert

You need advice on solutions, contact (+84) 909 840 002 MHP is always with you!

View Today :

View Today :  Views Last 30 days :

Views Last 30 days :  Total Views : 12907

Total Views : 12907