Snack Production

Requirements/challenges for the Snack production process

-

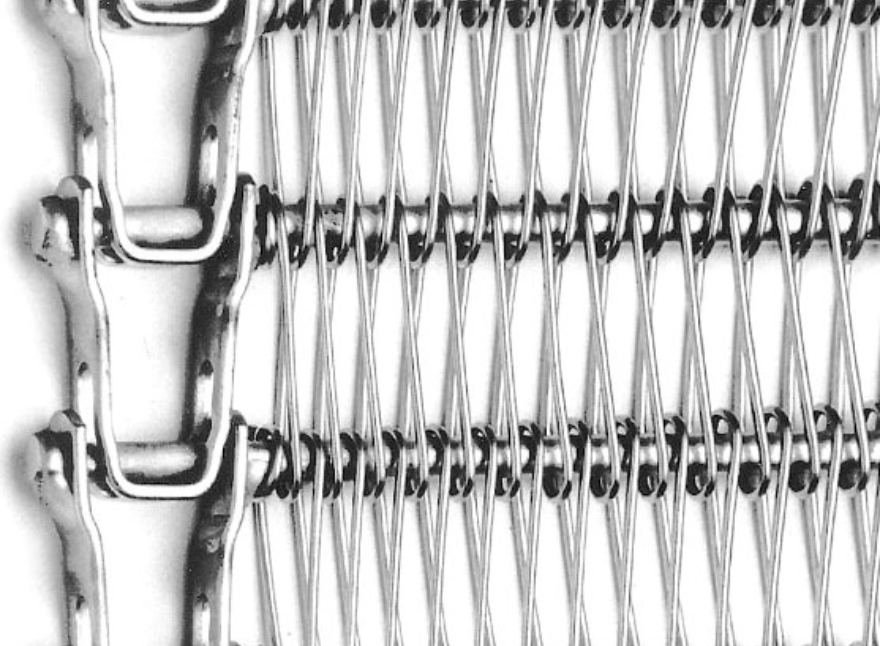

Belts are easily oxidized when exposed to a oil environment during frying, which reduces their service life

-

The snacks produced dust particles that migrated into the hinges, cracks, and crevices of the incline conveyor belt at the exit of one of its three dryers.This resulted in time-consuming cleaning and sanitation periods and significant unscheduled downtime

-

Cleaning often had to be repeated several times due to the belt’s failure to pass ATP swab tests

-

The belt was at the end of its life cycle and required regular inspections and repairs that resulted in up to two hours of additional downtime every week

Potato Frying Stages

-

High temperature performance, -10 ~ 50 degrees C (capable of up to 2000C), suitable for many different environments

-

The mesh is made of 304 stainless steel for corrosion resistance and high oxidation resistance in hot environments

-

After production, it is easy to clean, thereby helping to shorten maintenance time and save labor costs

-

No slipping or falling during operation

Inclined loading to prepare packing

-

ThermoDrive belting’s fully closed, homogeneous flat surface is easier to clean

-

Its lightweight design makes cleaning in place easier and less labor intensive

-

It only takes one person to easily lift the belt and clean the frame, reducing cleaning labor by 75% and cleaning time by 50%

-

Cleaning was made much simpler because there were no cracks and crevices

Contact an expert

You need advice on solutions, contact (+84) 909 840 002 MHP is always with you!

View Today :

View Today :  Views Last 30 days :

Views Last 30 days :  Total Views : 12907

Total Views : 12907