Rulmeca Roller Conveyor Unit Handling

Brand: Rulmeca – Italy, Thai Lan

Series:

-

Gravity conveyor rollers conveyors

-

Chain driven roller conveyors

-

Belt driven roller conveyors

-

Curve roller conveyors

-

Driver roller – RDF

Request a quote

For fastest support. Please Call (+84) 909 840 002

- Nationwide Delivery

- Technical Waranty

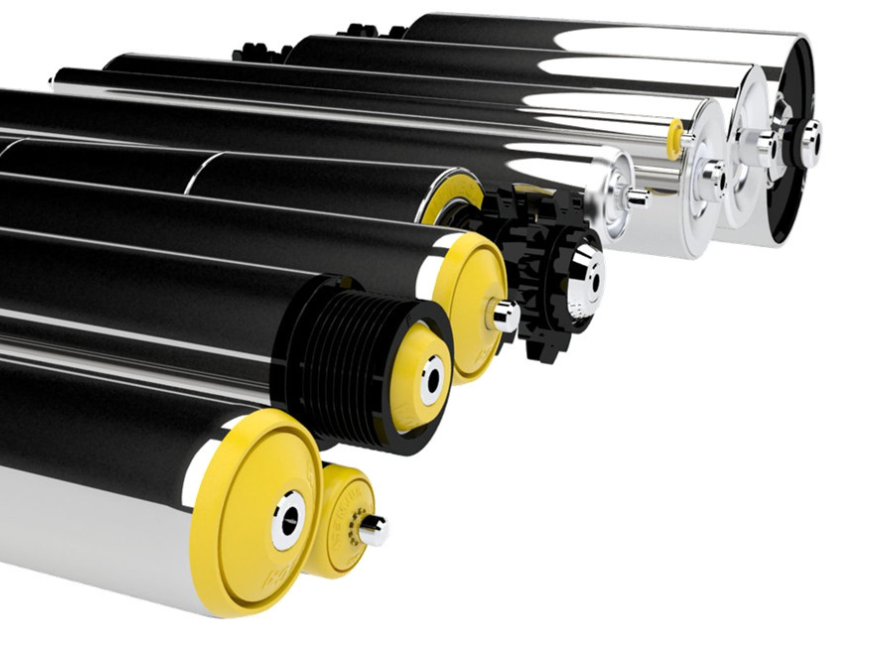

Gravity conveyor rollers conveyors

Gravity conveyor rollers are modular components specifically designed for the construction and functioning of idle roller conveyors. These material handling systems are made by a series of rollers supported by a carrying structure, designed to handle packages and unit items exactly by means of thrust or gravity, rather than power sources. Therefore, gravity conveyor rollers are easier to be installed and entail energy saving and low purchasing and maintenance costs

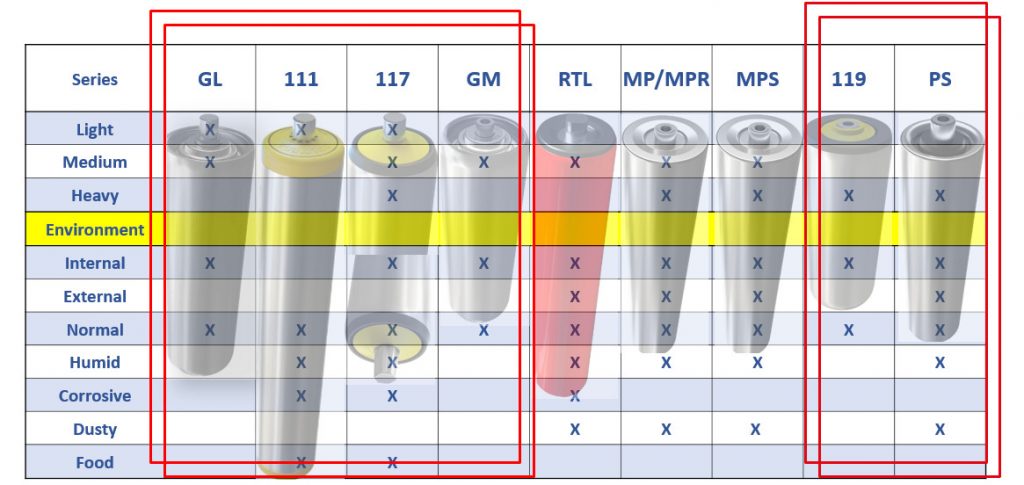

Series: GL, Food Conveyor Roller 111, Silent Conveyor Roller 117, GM, 119, PS, RTL, MP/MPR, MPS

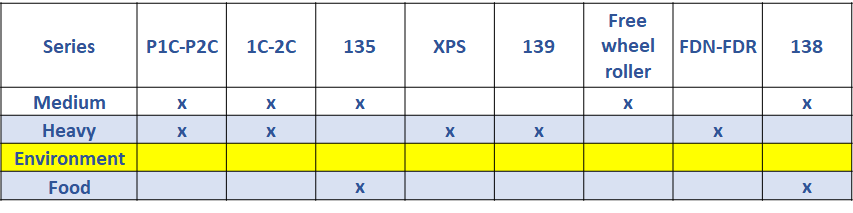

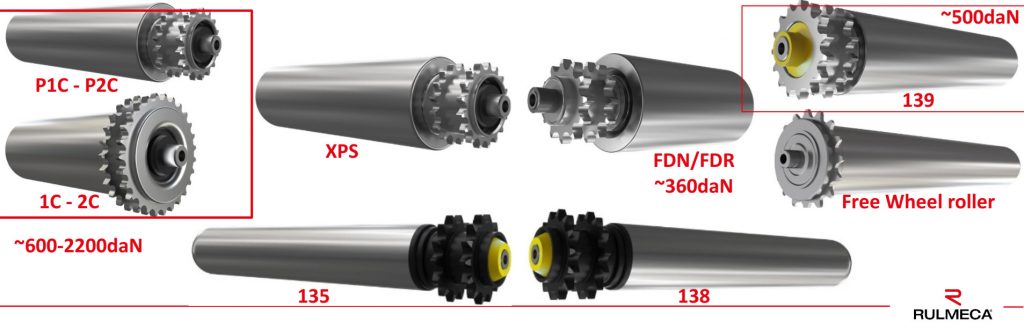

Chain driven roller conveyors

Chain driven roller conveyor systems consists in a series of rollers, fitted with sprockets, supported by a structure driven by a chain connected to motor. The precise joint between the rollers and the driving element is essential to ensure an efficient and accurate rotation: the chain locks into the sprockets making a high-friction contact which transfers the power to rollers and turn on the system

Series: P1C-P2C, 1C-2C 135, XPS 139, Free whee roller, FDN-FDR 138

Belt driven roller conveyors

Belt driven roller conveyor systems are a series of rollers, supported by a structure, which are driven by a belt. According to standard belt driving systems, motion can be transmitted with a flat-section belt, where a unique belt tensioned between the drive and the reversing pulley runs under rollers, or with belt rings where each roller is singly connected through a belt to a unique driving shaft located under rollers

Series

-

Grooves roller for round belt (117, G/GM)

-

135/138 for round, poly V, toothed belt

-

Series KRO tapered (curves roller)

-

Grooves for round belt and poly V belt

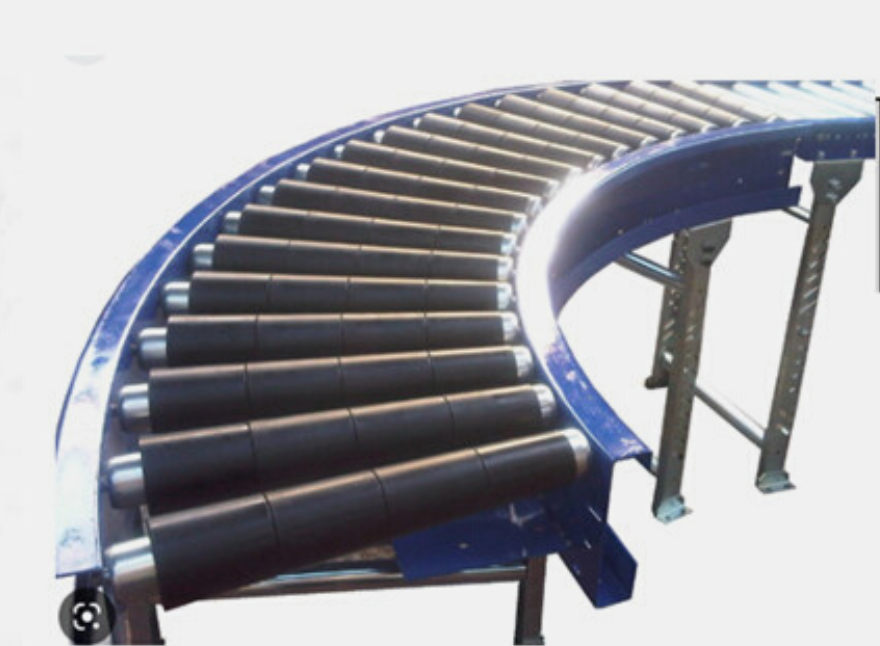

Curve roller conveyor

A curve roller conveyor allows materials to be transported around curves and corners, exploiting all the available floor space of the workplace. These systems are widely used in most unit handling applications, where large production lines or distribution chains require the continuous running of pallets, packages and single items along the entire process.

Application: Airport security and X-ray screening, postal parcel and e-commerce, anufacturing packaging and automation, distribution centres and warehousing, food and fish processing, beverage processing

Series: KRF, KRO, Double idler, KRM/S2m KRM/S3, KRO Driven

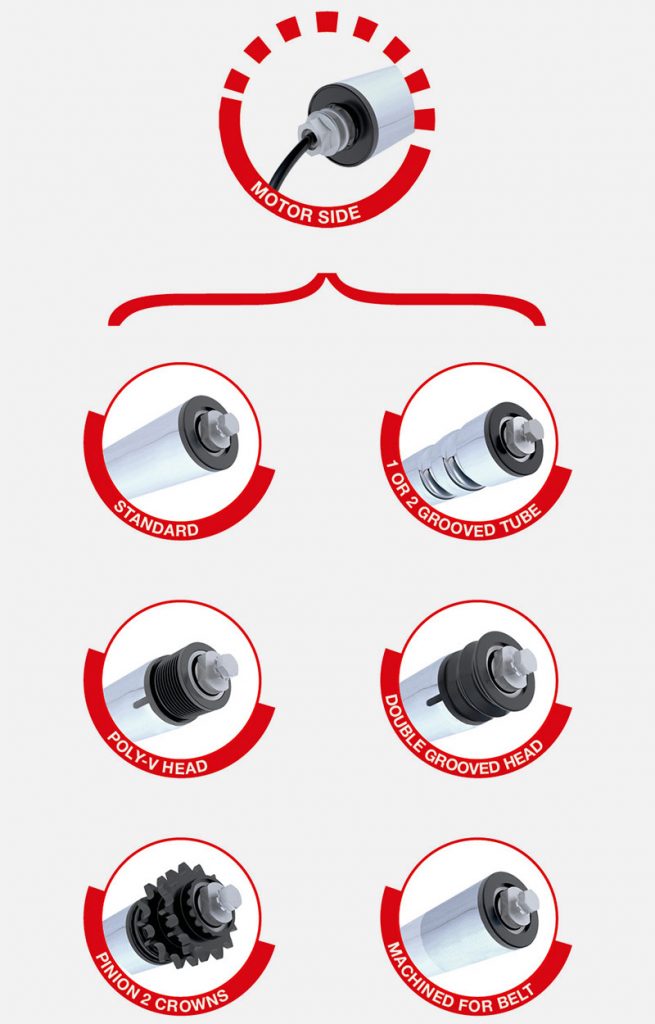

RDF – Rulmeca Drive Roller

1 side Motor – other side:

-

Grooves roller for round belt (117, G/GM)

-

135/138 for round, poly V belt

-

Series KRO tapered (curves roller)

-

Grooves for round belt and poly V belt

View Today :

View Today :  Views Last 30 days :

Views Last 30 days :  Total Views : 12907

Total Views : 12907