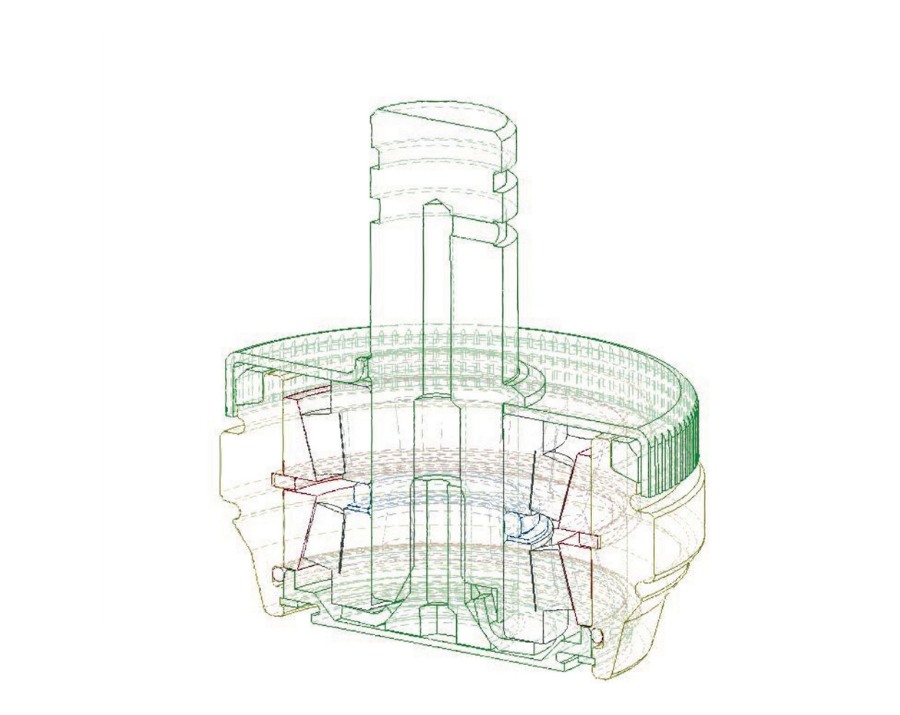

Seaming Chucks and Rolls

Brand: G7, Asian

Series: Seaming roll, Seaming chuck

Application:

-

For The Can Markers

-

For The Can Neries

-

Superficial coatings: CVD Coating, PVC Coating

Request a quote

For fastest support. Please Call (+84) 909 840 002

- Nationwide Delivery

- Technical Waranty

For The Can Markers

1 . AISI D2 standard steel, used in the majority of can-making applications;

2 . K360 (Or equivalent) – A Highly resistant tool steel resistant to brittle fracture, commonly used in weak chuck lip situations or for Easy Open ends;

3 . K390 (Or equivalent) – A sinterised stainless steel whose molecular structure offers extreme hardness, resistance against corrosion and wear compared to standard AISI D2;

4 . Stoody Metal®, a chrome and cobalt alloy obtained by a centrifuged casting offering the greatest strength against corrosion and wear. Designed for extreme working conditions.

For The Can Neries

1. AISI 440 standard stainless steel, used in the majority of applications;

2 . Cromax Stainless steel – Highly resistant against corrosion, frequently used for seaming chucks when working with foods of a high acidity level (mushrooms, brine, etc…);

3 . M390 (Or equivalent) Sinterised Stainless steel whose molecular structure offers extreme hardness and resistance against corrosion and wear compared to standard AISI 440;

4 . Stoody Metal®, a chrome and cobalt alloy obtained by a centrifuged casting offering the greatest strength against corrosion and wear. Designed for extreme working conditions.

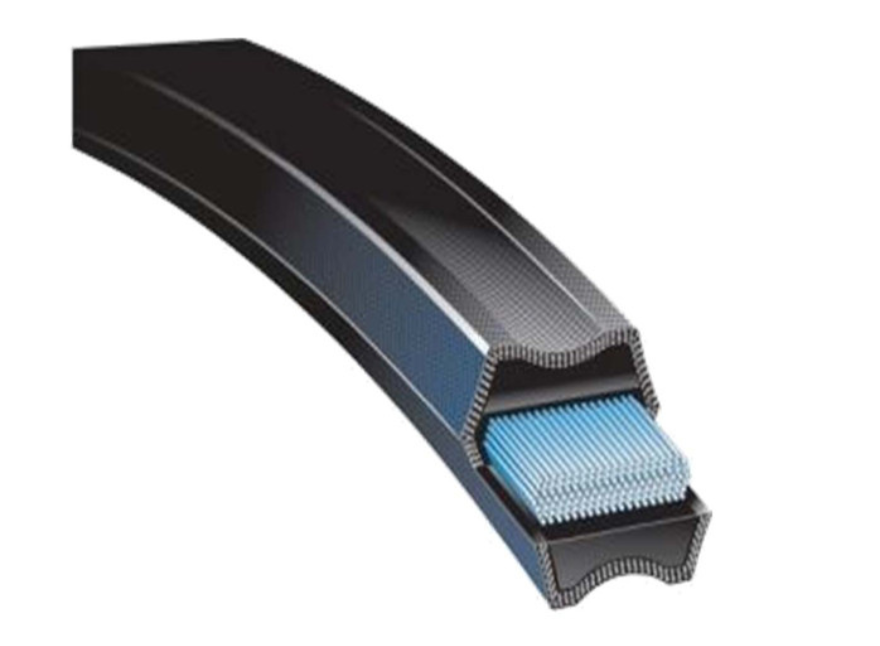

Superficial coatings

CVD Coating: |

PVC Coating |

||||||

|

|

View Today :

View Today :  Views Last 30 days :

Views Last 30 days :  Total Views : 12907

Total Views : 12907